The Importance of Timely Oil Seal Replacement in Combine Harvesters

Oil seals play a crucial role in the operation of a combine harvester. Over time, these seals can wear out, leading to oil leaks and reduced machinery performance. Timely replacement of damaged oil seals is essential for maintaining the efficiency and longevity of your harvester. This article highlights the importance of regular oil seal replacement and the impact it has on your equipment.

Why Timely Oil Seal Replacement Matters

Oil seals are designed to keep the machinery properly lubricated and prevent oil leaks, protecting critical components. However, as the seals age, they can become brittle, crack, or lose their sealing properties, leading to oil leakage and potential damage to other parts of the machinery.

Preventing Oil Leaks: Timely replacement of oil seals prevents leaks that can lead to system contamination, loss of lubrication, and increased wear on other components.

Extending Machinery Life: Replacing worn-out oil seals reduces the strain on other parts, ensuring the overall longevity and reliability of the combine harvester.

Maintaining Performance: By replacing oil seals on time, operators can ensure optimal performance, minimizing downtime and maximizing the efficiency of the harvester.

Avoiding Costly Repairs: Delaying the replacement of oil seals can result in more extensive damage to the machinery, leading to costly repairs and prolonged downtime.

Signs That Oil Seals Need Replacement

Visible Leaks: If oil is visibly leaking from any part of the machinery, it's a sign that the oil seals may be damaged and in need of replacement.

Loss of Lubrication: A decrease in lubrication levels or frequent oil changes can indicate that the oil seals are no longer functioning properly.

Unusual Noises: Grinding or squeaking noises during operation may signal that the oil seals are damaged or worn out, requiring immediate attention.

Decreased Performance: A noticeable drop in performance or efficiency could indicate that the oil seals are not properly sealing, leading to reduced lubrication and increased friction.

Conclusion

Replacing oil seals in a timely manner is critical to the ongoing performance and longevity of a combine harvester. By recognizing the signs of wear and replacing the seals when necessary, operators can prevent oil leaks, reduce repair costs, and ensure that their equipment runs smoothly for years to come.

SEO Keywords: Oil seal replacement, combine harvester oil seals, machinery maintenance, oil seal wear, machinery performance, oil leak prevention, oil seal damage, combine harvester repairs, farm equipment maintenance, oil seal degradation, equipment longevity, machinery reliability, timely replacement, lubrication issues, oil contamination, machinery upkeep, seal failure prevention, oil system maintenance, combine harvester maintenance, seal performance, machinery downtime.

SEO Description: Learn the importance of timely oil seal replacement in combine harvesters. Discover how replacing worn-out seals can prevent oil leaks, improve performance, and reduce costly repairs.

The Importance of Timely Oil Seal Replacement in Combine Harvesters

Oil seals play a crucial role in the operation of a combine harvester. Over time, these seals can wear out, leading to oil leaks and reduced machinery performance. Timely replacement of damaged oil seals is essential for maintaining the efficiency and longevity of your harvester. This article highlights the importance of regular oil seal replacement and the impact it has on your equipment.

Why Timely Oil Seal Replacement Matters

Oil seals are designed to keep the machinery properly lubricated and prevent oil leaks, protecting critical components. However, as the seals age, they can become brittle, crack, or lose their sealing properties, leading to oil leakage and potential damage to other parts of the machinery.

Preventing Oil Leaks: Timely replacement of oil seals prevents leaks that can lead to system contamination, loss of lubrication, and increased wear on other components.

Extending Machinery Life: Replacing worn-out oil seals reduces the strain on other parts, ensuring the overall longevity and reliability of the combine harvester.

Maintaining Performance: By replacing oil seals on time, operators can ensure optimal performance, minimizing downtime and maximizing the efficiency of the harvester.

Avoiding Costly Repairs: Delaying the replacement of oil seals can result in more extensive damage to the machinery, leading to costly repairs and prolonged downtime.

Signs That Oil Seals Need Replacement

Visible Leaks: If oil is visibly leaking from any part of the machinery, it's a sign that the oil seals may be damaged and in need of replacement.

Loss of Lubrication: A decrease in lubrication levels or frequent oil changes can indicate that the oil seals are no longer functioning properly.

Unusual Noises: Grinding or squeaking noises during operation may signal that the oil seals are damaged or worn out, requiring immediate attention.

Decreased Performance: A noticeable drop in performance or efficiency could indicate that the oil seals are not properly sealing, leading to reduced lubrication and increased friction.

Conclusion

Replacing oil seals in a timely manner is critical to the ongoing performance and longevity of a combine harvester. By recognizing the signs of wear and replacing the seals when necessary, operators can prevent oil leaks, reduce repair costs, and ensure that their equipment runs smoothly for years to come.

SEO Keywords: Oil seal replacement, combine harvester oil seals, machinery maintenance, oil seal wear, machinery performance, oil leak prevention, oil seal damage, combine harvester repairs, farm equipment maintenance, oil seal degradation, equipment longevity, machinery reliability, timely replacement, lubrication issues, oil contamination, machinery upkeep, seal failure prevention, oil system maintenance, combine harvester maintenance, seal performance, machinery downtime.

SEO Description: Learn the importance of timely oil seal replacement in combine harvesters. Discover how replacing worn-out seals can prevent oil leaks, improve performance, and reduce costly repairs.

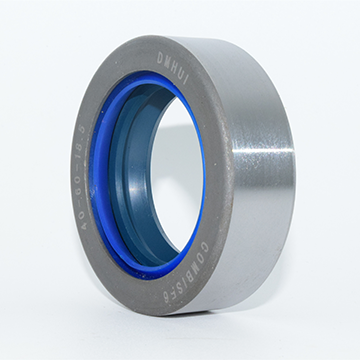

Industrial seals

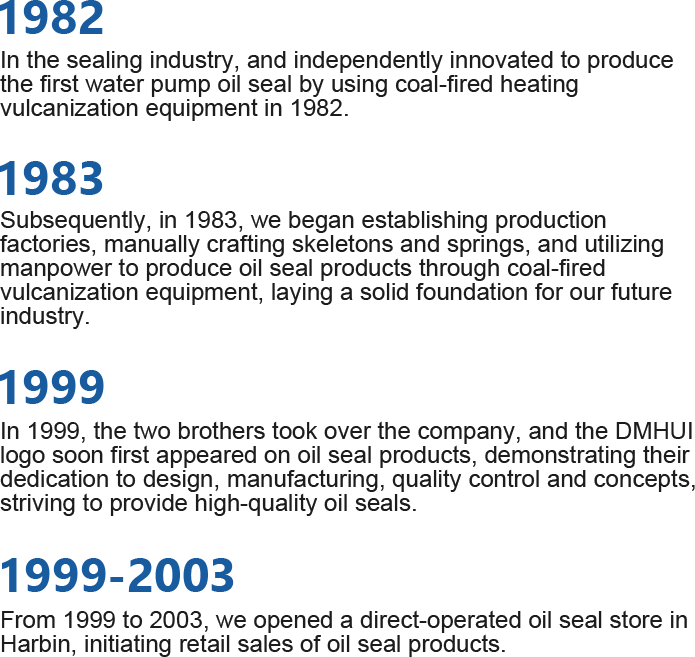

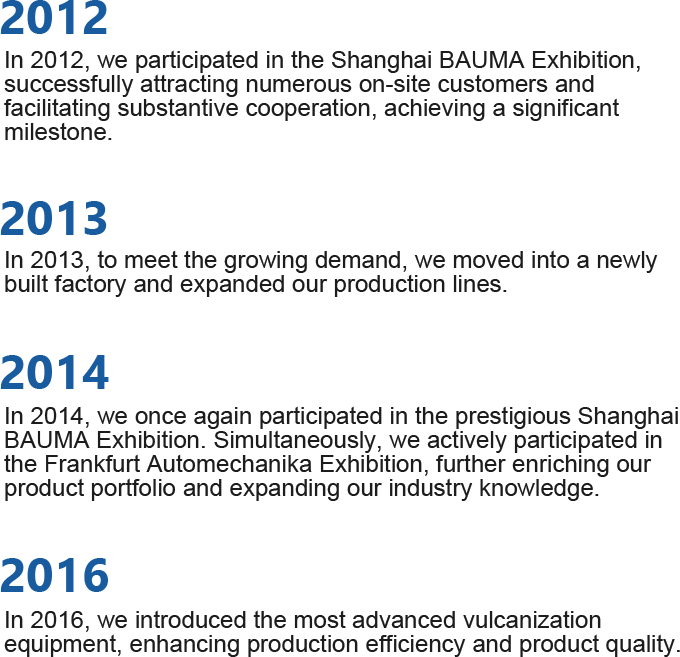

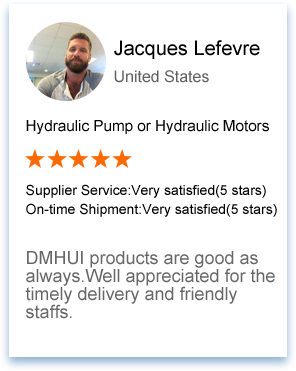

Since 1982, DMHUI has been a major sealing product manufacturer and solution provider in China.

Relying on more than 40 years of technical accumulation, we promote lean and digital assembly line production mode to ensure that our products have excellent quality, high consistency and large-scale delivery capabilities, and continue to provide customers with efficient and reliable sealing solutions.

DMHUI focuses on designing and manufacturing: construction machinery oil seals, large agricultural machinery oil seals, commercial vehicle oil seals, industrial oil seals and other customized rubber products.

DMHUI rotary shaft seals fully cover dynamic seals, static seals and extreme working conditions. After unremitting efforts, DMHUI brand sealing products have been recognized by manufacturers and dealers in the fields of oil drilling, construction machinery and agricultural machinery.

Our R&D department staff has rich professional knowledge. DMHUI is equipped with the most advanced rubber preforming machines, fully automatic vacuum vulcanizers and hundreds of advanced processing and precision testing equipment. Therefore, we can complete customized orders according to drawings or samples.

We have established a material laboratory to test all raw materials and conduct research on the most advanced materials.

In 2024, the "DMHUI" trademark was officially transferred to Demeihui Seals and completed the Madrid International Trademark Registration, marking the full acceleration of the brand's internationalization strategy. In order to efficiently respond to market demand, the company has established branches and warehouses in Ningbo and Shenzhen to build a global sales and service system.

drawings/samples, with advanced equipment and professional R&D

for quick responses.

email: info5@dmhuiseal.com

TEL: +86 19166350093

email: info2@dmhuiseal.com

Tel: +86 15323776895

email: info3@dmhuiseal.com

TEL: +86 19166350091

email: info4@dmhuiseal.com

TEL: +86 19166350092

Julu County Demeirui Mechanical Seal Factory

Address:

Fengyuan Street, Julu Development Zone, Julu County, Xingtai City, Hebei Province, China

DMHUI Sealing Technology (Shenzhen)Co., Ltd

Address:

411 Yunli Centre, No.19 ZhonghaoSecond Road, Longgang District,ShenzhenCity.GuangdongProvince, China

DMHUI Sealing Technology (Ningbo)Co., Ltd

Address:

Room 7088-1060, 7th Floor, No. 1558, Jiangnan Road, Ningbo High-tech Zone, Zhejiang Province, China

.png)

.jpg)